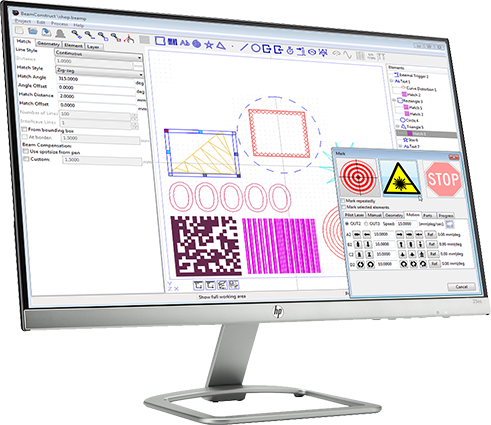

BeamConstruct is an integrated, stand-alone laser marking software solution for nearly all kinds of laser scanner, laser CNC and mechanical CNC applications.

It can be used for laser welding, cutting, engraving, marking, natural branding, milling as well as for rapid prototyping / SLS / 3D printing.

It offers more than only the common features, supports several laser scanner and CNC controllers and provides full support for industrial usage.

Laser marking or milling projects created within BeamConstruct can be sent to a scanner system or a mill out of the application directly or they can be used within a

custom visualisation and process control application created using the ControlRoom HMI and process control software.

So material processing projects generated with this application can be integrated seamless into existing machine control, there is no need to run the

CAD-interface of this application within a production environment.

Some of the key features of BeamConstruct:

- Several static primitives like lines, circles, spirals, rectangles, triangles, polygons, bezier-curves

- Different additional elements and object-types that can be combined with primitive geometries freely to easily create complex geometries

- Freely definable and combinable filling/hatching of elements using different complex modes and patterns including hatching of three-dimensional elements

- Dynamic elements like serial numbers, date, time, data set externally; they can be combined with:

- Text and barcode elements

- Text with support for all TrueType™ fonts and styles as well as speed-optimised laser-fonts

- Barcodes with support for DataMatrix, PDF417, EAN, UPC, GTIN, MaxiCode, Aztec, Codabar, USPS, EIHBCC-codes and much more

- Cutting of laser projects into smaller pieces that fit into the workspace and automated processing with integrated control of motion drives

- Smart Interface for Industry 4.0/Smart Factory applications

- Freely configurable Predicitive Maintenance for mechanical and optical devices

- Repeated processing of laser vector data with integrated motion controlling (one direction, rotational or X-Y-tables)

- Support for several scanner controller cards like HALaser Systems™ E1701D, HALaser Systems™ E1702S, HALaser Systems™ E1803D, Scanlab™ RTC4™ / RTC5™ / RTC6™ / RTCscanalone™, SCAPS™ USC-1™ / USC-2™ / USC-3™ and others more

- Support of all common raster/bitmap image formats

- Support for several different 2D import formats such as Comma Separated Values (CSV), AutoCAD DXF, GCode (GCODE/CNC/NCC), Gerber RS-247-X (STC/STS), HPGL (PLT), Scalable Vector Graphics (SVG), XML Paper Specification (XPS)

- Support for several different 3D import formats such as 3D Manufacturing Format (3MF), 3D Studio (3DS/ASE), Additive Manufacturing Format (AMF), Biovision (BVH), Common Layer Interface (CLI), LightWave (LWO/LWS), Object File Format (OFF), Polygon / Stanford Triangle (PLY), RenderWare (RWX), Sense8 WorldToolkit / Neutral File Format (NFF), Surface Tesselation Language (STL), WaveFront OBJ Files

- Full machine integration and automation possibilities via process control solution that is able to embed fully featured laser marking projects

- Full support for 3D editing and marking, all geometries can be edited and modified in all three dimensions easily without artificial restrictions

- Freely rotateable and movable 3D view to inspect generated laser projects

- Slicing of solid 3D models for 2D layer based rapid prototyping or depth engraving applications

- CAD and WYSIWYG capabilities of laser project editor

- Software available for Windows™ and Linux™

- Can be translated into every language, English, Deutsch, Italiano, Yкраїнський, 简体中文 and others already available

PLEASE

CLICK HERETO GET AN FULL OVERVIEW ABOUT THE FEATURES AND

FUNCTIONS OF BeamConstruct LASER MARKING SOFTWARE